Piping Material Engineering_May 2025

Team Piping Engineering

Founder Team Piping Engineering

$ 120

1 already enrolled!

Advanced course for professionals

Piping Material Engineering_May 2025

Trainers feedback

4

(21 reviews)

Team Piping Engineering

Founder Team Piping Engineering

Course type

Instructor led live training

Course duration

0 Hrs

Course start date & time

Coming in Next Month

Language

English

This course format is where trainer will explain you the subject via online live session. Date and time are not decided yet but it will be planned within next 2 weeks after you enroll & pay for this course?. Get in touch with our team if any clarification is required.

Why enroll

Comprehensive Understanding: Participants will gain an in-depth knowledge of piping engineering, covering design principles, material specifications, and industry standards comprehensively.

Practical Skills: The course includes hands-on learning with real-world examples and case studies, enabling participants to apply theoretical knowledge to practical scenarios effectively.

Industry-Relevant Insights: Learn about the latest trends, technologies, and best practices in piping engineering, making participants valuable assets to their organizations.

Enhanced Problem-Solving Abilities: Develop advanced skills to diagnose and solve piping design and material specification issues, improving system efficiency and reliability.

Career Advancement: Enhance your professional profile with specialized knowledge and skills in piping engineering, opening up opportunities for career growth in engineering design and project management.

Opportunities that awaits you!

Earn a course completion certificate

Add this credential to your LinkedIn profile, resume, or CV. Share it on social media and in your performance review

Course details

To equip participants with a comprehensive understanding of piping design, material specifications, and industry standards, enabling them to effectively design, analyze, and manage piping systems in various industrial applications.

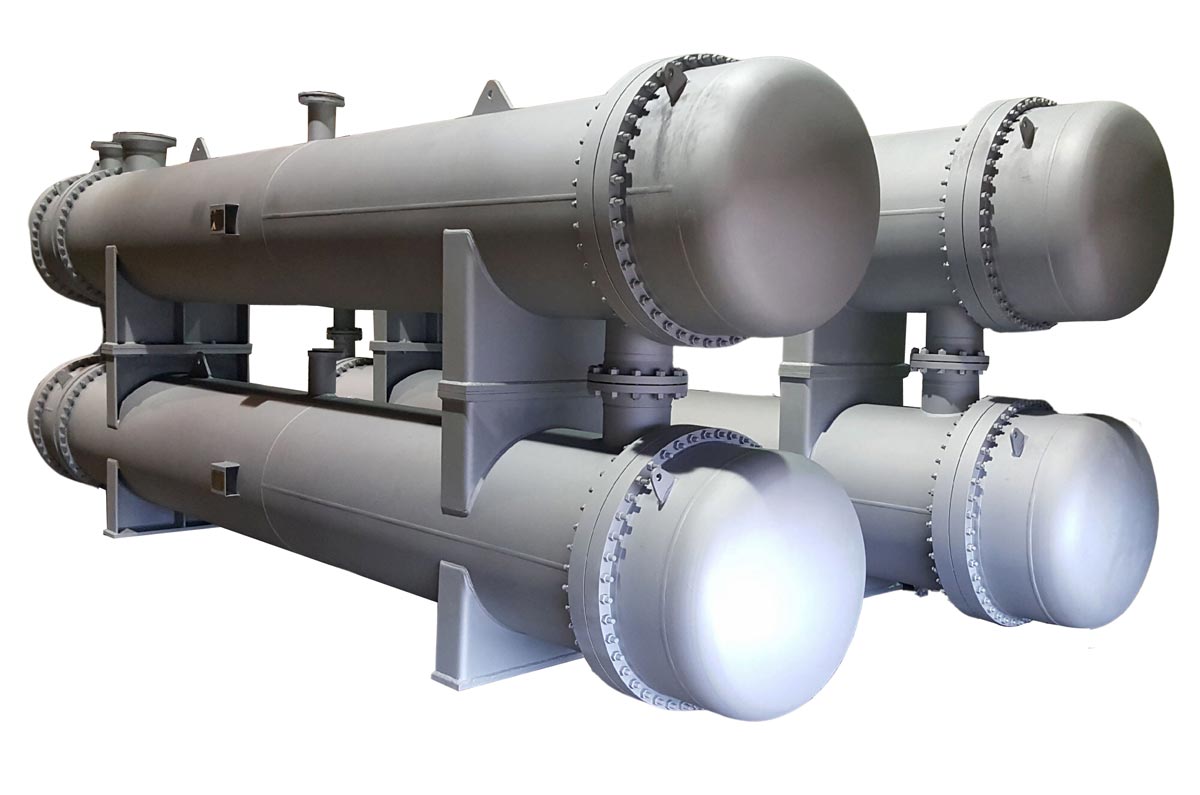

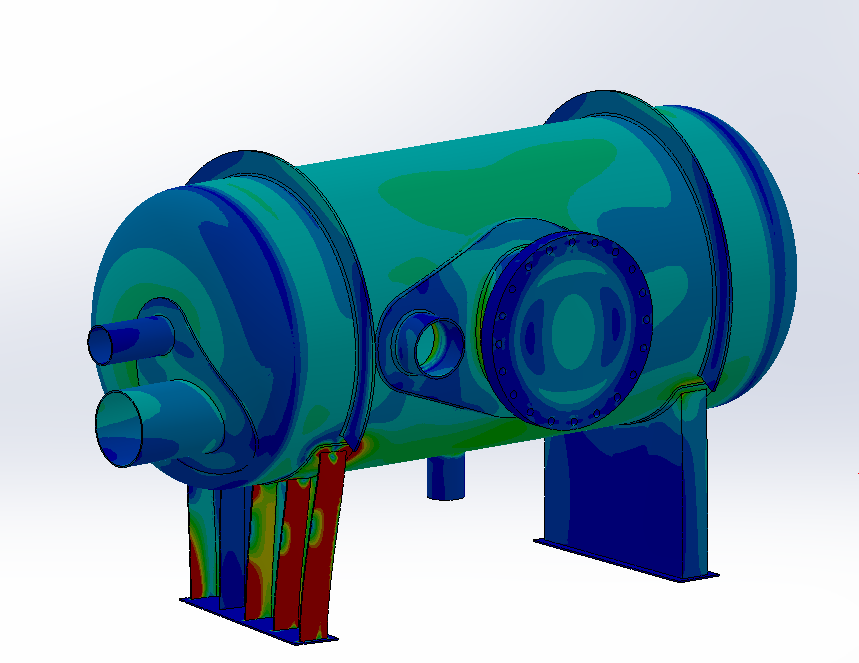

This course covers essential aspects of piping engineering, including component identification, valve selection, wall thickness calculations, adherence to codes and standards, material specifications, special parts, and detailed procedures for jacketed piping, piping line lists, and the enquiry process. Gain practical knowledge and skills through a structured syllabus that bridges theoretical concepts with real-world applications.

Course suitable for

Oil & Gas Chemical & Pharmaceutical Energy & Utilities Piping & Layout Chemical & Process Petroleum

Key topics covered

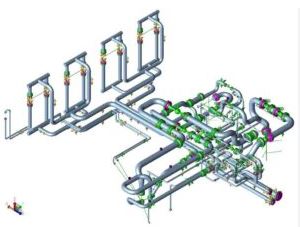

Introduction and Piping Components

Overview of piping systems

Identification and functions of piping components

End connections: types and applications

Valves

Types of valves and their applications

Valve selection criteria

Installation and maintenance considerations

Internal Pressure Wall Thickness Calculation

Fundamentals of wall thickness calculation

ASME B31.3 code requirements

Practical examples and calculation techniques

Branch Calculation and External Pressure Wall Thickness Calculation

Branch reinforcement requirements

External pressure considerations

Calculation methods and examples

Codes & Standards and ASME B31.3

Overview of relevant codes and standards

Detailed study of ASME B31.3

Application of codes in piping design

Details of Few Common ASTM Standards

Introduction to ASTM standards

Common ASTM standards used in piping

Material properties and selection criteria

Piping Material Specification & Fluid List in Detail

Understanding piping material specifications (PMS)

Detailed fluid list and compatibility

Material selection for different process conditions

Special Parts

Overview of special piping components

Design and application of special parts

Installation and maintenance considerations

Jacketed Piping with Steam Trap in Detail

Design and application of jacketed piping

Steam trap selection and installation

Thermal insulation and efficiency considerations

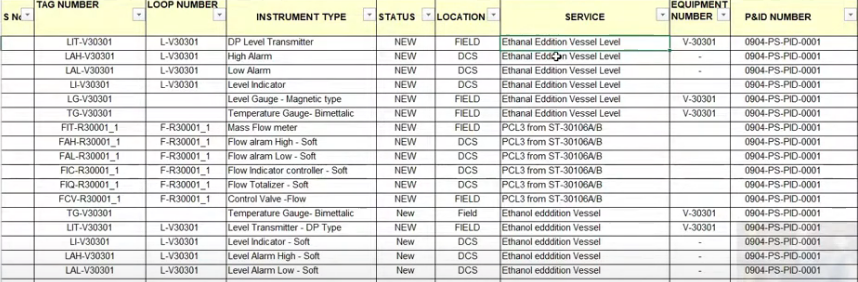

Piping Line List and Piping MTO

Creating and maintaining a piping line list

Understanding piping material take-off (MTO)

Importance in project management and cost estimation

Explaining Enquiry and TBA Process

Enquiry process for piping components

Understanding the technical bid analysis (TBA) process

Best practices for ensuring accurate and efficient procurement

Training details

This is a live course that has a scheduled start date.

Live session

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

$ 120

- $ 0 Early bird discount

Coming in Next Month

Questions and Answers

A: Common materials used in piping systems include carbon steel, stainless steel, copper, PVC, CPVC, and ductile iron. Carbon steel is widely used for high-pressure and high-temperature applications such as oil and gas pipelines. Stainless steel is preferred for corrosive environments and sanitary applications, such as in food processing. Copper is mainly used for water supply and HVAC systems due to its excellent thermal conductivity and corrosion resistance. PVC and CPVC are used for low-pressure and corrosive fluid transport, especially in chemical and wastewater systems. Ductile iron is often employed in water and sewage pipelines because of its strength and durability. For more details, you can refer to the ASME B31 piping codes: https://www.asme.org/codes-standards.

A: Selecting the appropriate material for high-temperature piping depends on factors such as operating temperature, pressure, fluid chemistry, mechanical strength, and codes compliance. Materials like carbon steel (e.g., ASTM A106 Grade B) are commonly used up to 400°C. For temperatures beyond this, alloy steels such as chromium-molybdenum steels (e.g., P22, P91) may be chosen due to their enhanced creep resistance and strength at elevated temperatures. It's also essential to consider thermal expansion, corrosion potential, and weldability. Consulting standards such as ASME B31.3 and material datasheets assists in making the right choice. Detailed info can be found here: https://www.materialsperformance.com.

A: Corrosion in piping materials is influenced by factors including the type of fluid (acidic, alkaline, saline), temperature, pressure, flow velocity, and environmental exposure (e.g., soil, atmospheric conditions). Oxygen content and microbial activity can also accelerate corrosion. Mitigation strategies include selecting corrosion-resistant materials (stainless steel, alloys), applying protective coatings and linings, cathodic protection, controlling process parameters (pH, temperature), and regular maintenance with inspections. For example, in sour gas environments, duplex stainless steel or corrosion-resistant alloys (CRAs) are commonly used. For extensive guidance, refer to NACE International's standards: https://www.nace.org.

A: Seamless pipes are manufactured by extruding a solid billet to form a hollow tube without any welded joint, leading to uniform strength and no potential weak points. Welded pipes are formed by rolling a plate and welding the seam. Seamless pipes are preferred in high-pressure, critical applications due to their superior strength and reliability, whereas welded pipes are more cost-effective and suitable for lower pressure systems. However, advancements like high-frequency welded (HFW) pipes have improved welded pipe quality. The choice impacts design, cost, and inspection requirements since welded seams require additional non-destructive testing (NDT). More details can be found at ASTM standards: https://www.astm.org.

A: Piping codes and standards, such as ASME B31 series, API standards, and ASTM specifications, provide mandatory guidelines for material selection, design, fabrication, and testing to ensure safety, reliability, and compatibility. They define acceptable materials, pressure-temperature ratings, corrosion allowances, joint design, and inspection protocols. Compliance reduces risks of failure, streamlines engineering decisions, and ensures regulatory approval. For example, ASME B31.3 covers process piping materials and design criteria. Familiarity with relevant codes is essential for engineers working on piping systems. Official resources: https://www.asme.org/codes-standards.

A: Temperature fluctuations cause thermal expansion and contraction, leading to stresses, fatigue, and potential material degradation in piping systems. Materials must have adequate thermal expansion coefficients, ductility, and mechanical strength to handle cyclic temperature changes without cracking or deformation. Additionally, low-temperature embrittlement and high-temperature creep need evaluation. For example, carbon steel is suitable for moderate temperatures but may become brittle at very low temps, where materials like stainless steel or low-temperature carbon steel grades are preferred. To accommodate expansion, design elements such as expansion loops and joints are incorporated. Detailed considerations are included in ASME B31 codes.

A: Corrosion-resistant alloys (CRAs) are metals or alloys specifically engineered to withstand aggressive environments that cause corrosion, such as sour gas (H2S), chloride-rich media, or highly acidic conditions. Common CRAs include duplex stainless steels, super duplex, alloy 20, Inconel, and Hastelloy. These materials provide superior resistance against pitting, crevice corrosion, and stress corrosion cracking. They are widely used in chemical processing, offshore oil and gas, geothermal plants, and desalination facilities. Though more expensive, they enhance system longevity and reduce maintenance costs. More information can be found at NACE: https://www.nace.org/resources/corrosion-central.

A: Welding procedures are crucial to ensure joint integrity, mechanical strength, and corrosion resistance in piping fabrication. Improper welding can lead to defects like cracks, porosity, or weld metal corrosion, compromising system safety. Material compatibility, including matching filler materials and base metals, influences weld quality and performance. For example, welding stainless steel to carbon steel requires specific filler metals and procedures to prevent corrosion and maintain strength. Additionally, preheat and post-weld heat treatment may be necessary for certain alloys. Codes like ASME Section IX provide mandatory welding procedure qualification guidelines. Comprehensive guidelines can be found at ASME: https://www.asme.org/codes-standards.

A: Designing piping for corrosive chemicals requires careful consideration of material compatibility, corrosion allowances, fluid properties (pH, concentration), temperature, pressure, and flow velocity. Materials should resist chemical attack, so alloys like Hastelloy, PTFE-lined pipes, or PVC/CPVC are commonly chosen. Additionally, designing for minimal dead legs, adequate drainage, and ease of inspection helps mitigate corrosion. Protective measures such as coatings, cathodic protection, and corrosion inhibitors can be incorporated. Understanding industry standards such as API 570 and NACE guidelines is also vital to ensure safety and durability. Further reading is available at: https://www.api.org.

More from Same Author

- Technical Courses

- Articles

Watch to learn anytime

245

1

E-Learning

Unlimited access

Watch to learn anytime

435

E-Learning

Unlimited access

4 (19)

Watch to learn anytime

634

E-Learning

Unlimited access

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

4 (19)

Watch to learn anytime

26

28

E-Learning

Unlimited access

4 (17)

Watch to learn anytime

881

7

E-Learning

Unlimited access

4

Watch to learn anytime

1474

2

E-Learning

Unlimited access

More Training & Development option to expand your reach

- Technical courses

- Soft-skill courses

- Seminars & Conferences

- Articles & Blogs

5

Instructor led live training

459

1

Online

Live courses

September 22

9 Hrs

Beginner

4 (23)

Instructor led live training

335

1

Online

Live courses

October 11

14 Hrs

Advanced

4 (23)

Instructor led live training

541

Online

Live courses

October 11

4 Hrs

Intermediate