Electrical System Design

Subodh Sawant

Design Manager-Electrical Engineering (HOD)

$ 4286

Beginner course for learners

Electrical System Design

Trainers feedback

0

(0 reviews)

Subodh Sawant

Design Manager-Electrical Engineering (HOD)

Course type

Instructor led live training

Course duration

0 Hrs

Course start date & time

Coming in Next Month

Language

English

This course format is where trainer will explain you the subject via online live session. Date and time are not decided yet but it will be planned within next 2 weeks after you enroll & pay for this course?. Get in touch with our team if any clarification is required.

Why enroll

Master the skills needed for electrical system design and installation.

Learn to assess power requirements and conduct site surveys.

Understand regulatory standards (IEC, NEC) and ensure compliance.

Gain hands-on experience in selecting components and designing protection systems.

Design lighting systems and integrate energy-efficient solutions.

Learn about short circuit analysis, renewable energy integration, and automation.

Develop expertise in system commissioning and maintenance.

Prepare for career growth in sectors like construction, manufacturing, and utilities.

Practical knowledge to design and implement safe, reliable, and sustainable electrical systems.

Enroll today and shape the future of electrical engineering.

Opportunities that awaits you!

Earn a course completion certificate

Add this credential to your LinkedIn profile, resume, or CV. Share it on social media and in your performance review

Course details

Electrical System Design

( Course Duration in Hours : 60 Hrs.)

1. Understanding Requirements

Load Analysis: Identifying the power requirements for different electrical loads (machinery, lighting, HVAC, etc.).

Site Survey: Assessing the physical location for installation constraints.

Regulatory Standards: Reviewing applicable codes, such as IEC, NEC, or local standards.

2. Preliminary Design

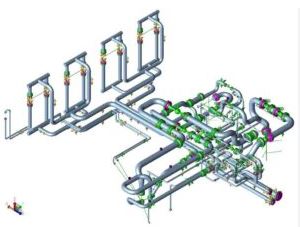

Single-Line Diagram (SLD): Developing a simplified representation of the electrical distribution network, showing how the main components (transformers, switchgear, etc.) are connected.

Load Calculation: Determining power consumption and sizing the electrical system components (transformers, switchgear, cables) based on demand.

Power Source Design: Deciding on the type of power source (utility grid, generators, renewable energy sources).

3. Component Selection

Cables and Wiring: Choosing appropriate conductor sizes based on current ratings and voltage drops.

Transformers: Selecting transformers based on load demand, voltage levels, and system configuration.

Switchgear & Protection Devices: Sizing circuit breakers, fuses, and relays for system protection.

Earthing/Grounding: Designing an effective earthing system to prevent electrical hazards.

4. System Protection Design

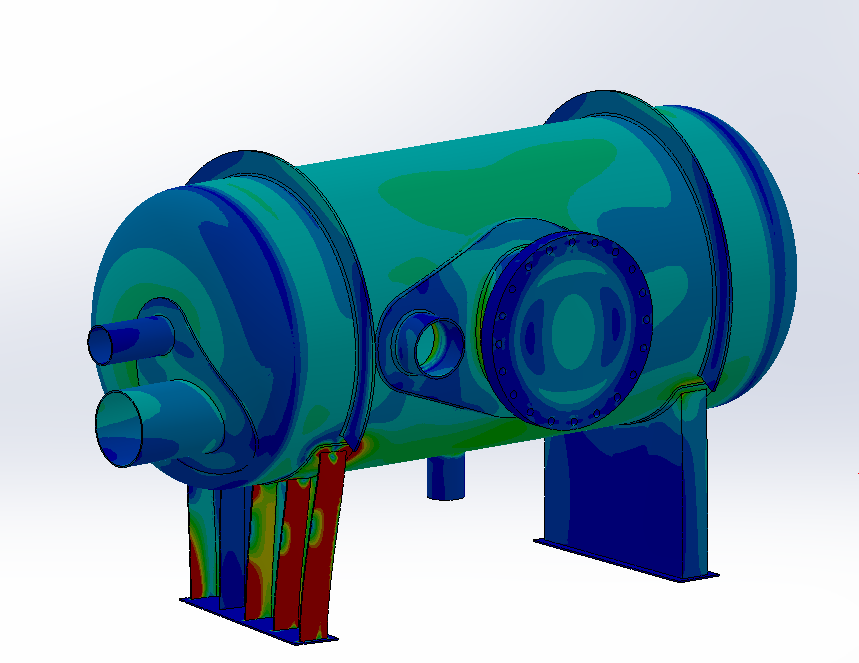

Short Circuit Analysis: Evaluating the potential fault current in the system and selecting devices to protect against overcurrent and short circuits.

Coordination Study: Ensuring that protection devices (relays, breakers) are coordinated for proper fault isolation without unnecessary downtime.

Arc Flash Study: Assessing potential arc flash hazards and designing the system to mitigate risks.

5. Lighting Design

Interior/Exterior Lighting: Designing lighting systems based on luminance requirements and energy efficiency standards.

Emergency Lighting: Integrating emergency and exit lighting for safety in case of power failure.

6. Distribution System Design

Cable Routing: Planning cable trays, conduits, and routing paths for minimal interference.

Busbar Design: For high-power systems, busbar sizing and configuration need to be considered.

7. Control and Automation

Building Automation Systems (BAS): Integrating controls for lighting, HVAC, and security systems.

Supervisory Control and Data Acquisition (SCADA): Designing SCADA systems for monitoring and controlling electrical equipment.

8. Energy Efficiency & Sustainability

Energy Auditing: Incorporating energy-saving strategies and selecting energy-efficient equipment.

Renewable Integration: Designing systems for solar, wind, or other renewable sources where applicable.

9. Documentation and Approvals

Detailed Drawings: Creating final circuit diagrams, layouts, and equipment details.

Bill of Materials (BOM): Listing all components required for installation.

Compliance Review: Ensuring the design meets regulatory requirements and securing necessary permits.

10. Installation and Commissioning

Installation Supervision: Overseeing the installation process to ensure it matches the design.

Testing & Commissioning: Conducting tests to validate system performance, including insulation resistance, continuity checks, and functional testing of protection systems.

11. Operation & Maintenance Planning

Maintenance Strategy: Developing a preventive maintenance plan for the system.

As-Built Drawings: Updating design documents to reflect any changes made during construction for future reference.

Course suitable for

Oil & Gas Energy & Utilities Automotive Electrical Instrumentation Health, Safety & Environmental

Key topics covered

1. Understanding Requirements

Load Analysis: Identifying the power requirements for different electrical loads (machinery, lighting, HVAC, etc.).

Site Survey: Assessing the physical location for installation constraints.

Regulatory Standards: Reviewing applicable codes, such as IEC, NEC, or local standards.

2. Preliminary Design

Single-Line Diagram (SLD): Developing a simplified representation of the electrical distribution network, showing how the main components (transformers, switchgear, etc.) are connected.

Load Calculation: Determining power consumption and sizing the electrical system components (transformers, switchgear, cables) based on demand.

Power Source Design: Deciding on the type of power source (utility grid, generators, renewable energy sources).

3. Component Selection

Cables and Wiring: Choosing appropriate conductor sizes based on current ratings and voltage drops.

Transformers: Selecting transformers based on load demand, voltage levels, and system configuration.

Switchgear & Protection Devices: Sizing circuit breakers, fuses, and relays for system protection.

Earthing/Grounding: Designing an effective earthing system to prevent electrical hazards.

4. System Protection Design

Short Circuit Analysis: Evaluating the potential fault current in the system and selecting devices to protect against overcurrent and short circuits.

Coordination Study: Ensuring that protection devices (relays, breakers) are coordinated for proper fault isolation without unnecessary downtime.

Arc Flash Study: Assessing potential arc flash hazards and designing the system to mitigate risks.

5. Lighting Design

Interior/Exterior Lighting: Designing lighting systems based on luminance requirements and energy efficiency standards.

Emergency Lighting: Integrating emergency and exit lighting for safety in case of power failure.

6. Distribution System Design

Cable Routing: Planning cable trays, conduits, and routing paths for minimal interference.

Busbar Design: For high-power systems, busbar sizing and configuration need to be considered.

7. Control and Automation

Building Automation Systems (BAS): Integrating controls for lighting, HVAC, and security systems.

Supervisory Control and Data Acquisition (SCADA): Designing SCADA systems for monitoring and controlling electrical equipment.

8. Energy Efficiency & Sustainability

Energy Auditing: Incorporating energy-saving strategies and selecting energy-efficient equipment.

Renewable Integration: Designing systems for solar, wind, or other renewable sources where applicable.

9. Documentation and Approvals

Detailed Drawings: Creating final circuit diagrams, layouts, and equipment details.

Bill of Materials (BOM): Listing all components required for installation.

Compliance Review: Ensuring the design meets regulatory requirements and securing necessary permits.

10. Installation and Commissioning

Installation Supervision: Overseeing the installation process to ensure it matches the design.

Testing & Commissioning: Conducting tests to validate system performance, including insulation resistance, continuity checks, and functional testing of protection systems.

11. Operation & Maintenance Planning

Maintenance Strategy: Developing a preventive maintenance plan for the system.

As-Built Drawings: Updating design documents to reflect any changes made during construction for future reference.

Training details

This is a live course that has a scheduled start date.

Live session

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

$ 4286

- $ 0 Early bird discount

Coming in Next Month

Questions and Answers

A: An electrical distribution system primarily consists of transformers, switchgear, circuit breakers, busbars, and protective relays. Transformers step down high voltage electricity to lower voltages suitable for end-users. Switchgear controls the flow of electricity and provides protection by enabling the isolation of equipment. Circuit breakers interrupt faulty circuits to prevent damage. Busbars serve as a junction point for power distribution. Protective relays detect faults and trigger circuit breakers. For more detailed information, you can refer to the IEEE Power & Energy Society resources at https://www.ieee-pes.org/.

A: Load demand calculation involves estimating the total power consumption of all electrical devices connected to the system. This includes assessing the power rating (in kW or VA) and the duty cycle of each device. The diversity factor and demand factor are applied to account for simultaneous usage and variability. The general formula is: Total Load = Sum of individual loads × Diversity Factor × Demand Factor. Understanding these factors is crucial for accurate design to avoid under-sizing or over-sizing equipment. The National Electrical Code (NEC) Handbook provides useful guidelines for load calculations: https://www.nfpa.org/nec.

A: AC (Alternating Current) and DC (Direct Current) systems differ primarily in the direction of current flow. AC current periodically reverses direction, while DC flows in a single direction. AC systems are commonly used for power distribution due to their ability to easily transform voltages using transformers, which makes long-distance transmission efficient. DC is often used in battery-powered devices, electronics, and applications requiring stable voltage supply. Additionally, AC systems can be more complex due to phases and harmonics, whereas DC systems are simpler but may have higher transmission losses over long distances. For deeper insight, visit: https://www.energy.gov/eere/vehicles/articles/ac-vs-dc-electricity.

A: Protective relays are devices that monitor electrical circuits for abnormal conditions such as faults or overloads. They detect these issues and send signals to circuit breakers to isolate the faulty part, preventing damage to equipment and ensuring safety. Protection relays enhance the reliability and stability of electrical systems by minimizing outage durations and preventing cascade failures. Modern protection relays can be electromechanical, solid-state, or digital (microprocessor-based). Understanding their operation is fundamental for designing secure and robust electrical systems. More details can be found at the IEEE guide on Protection and Control: https://resourcecenter.ieee-pes.org/protection-control.

A: Selecting a transformer rating involves estimating the maximum load that will be connected, considering future expansion, and including safety margins. Key factors include the total connected load (in kVA), load types (continuous or intermittent), ambient temperature, and installation conditions. Transformers should be sized to operate near their rated capacity for efficiency but avoid running overloaded to reduce overheating risks. It's also vital to consider standards such as ANSI and IEEE guidelines. A practical approach is to select a transformer with a rating about 20-25% higher than peak calculated load. Comprehensive selection criteria are available in the IEEE Transformer Guide: https://standards.ieee.org/standard/C57_91-2011.html.

More from Same Author

- Technical Courses

- Articles

4 (19)

Watch to learn anytime

28

E-Learning

Unlimited access

Instructor led live training

118

Online

Live courses

October 13

15 Hrs

5

Instructor led live training

893

195

Online

Live courses

September 15

1 Hrs

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

4

Watch to learn anytime

961

2

E-Learning

Unlimited access

Watch to learn anytime

1603

E-Learning

Unlimited access

4

Watch to learn anytime

1958

10

E-Learning

Unlimited access

More Training & Development option to expand your reach

- Technical courses

- Soft-skill courses

- Seminars & Conferences

- Articles & Blogs

5

Instructor led live training

459

1

Online

Live courses

September 22

9 Hrs

Beginner

4 (23)

Instructor led live training

335

1

Online

Live courses

October 11

14 Hrs

Advanced

4 (23)

Instructor led live training

541

Online

Live courses

October 11

4 Hrs

Intermediate