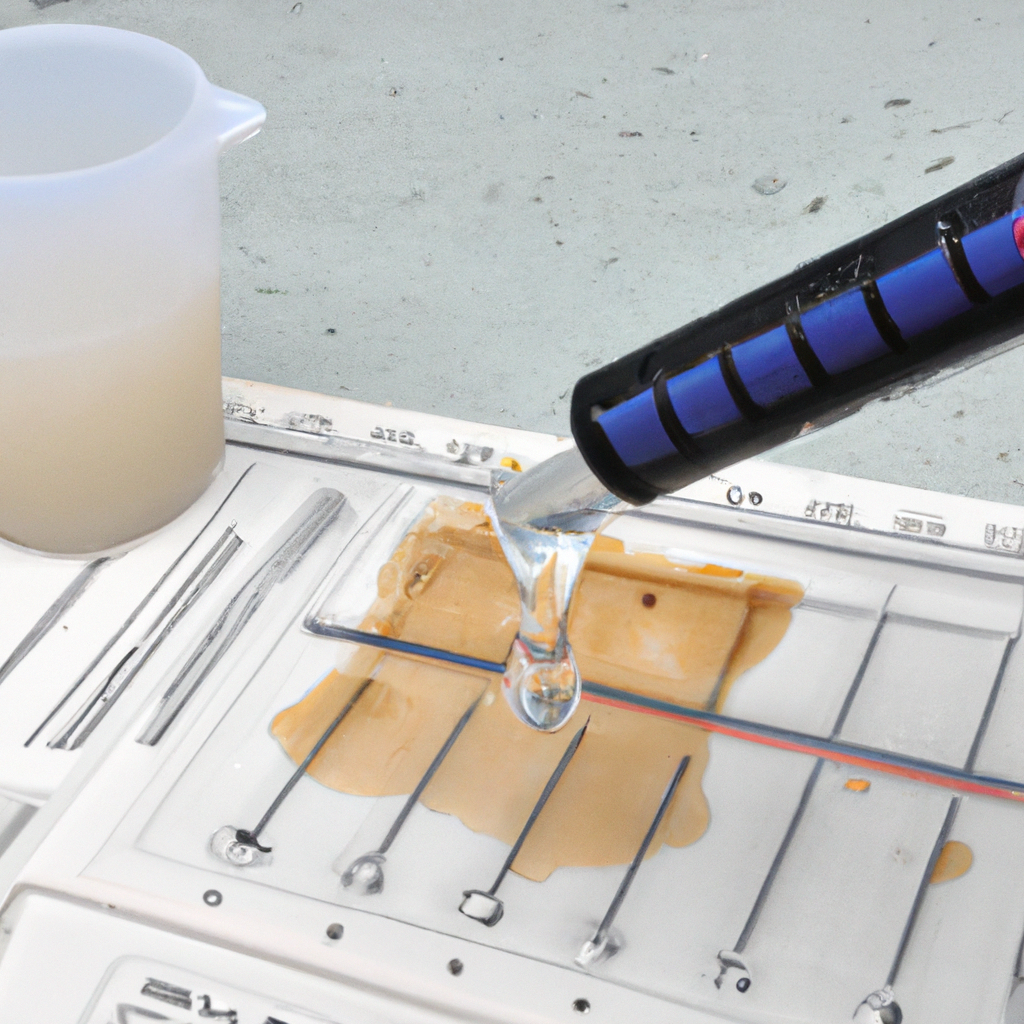

Liquid Penetrant Testing-Practical Demonstration

$ 504

0 already enrolled!

Opportunities that awaits you!

Earn a course completion certificate

Add this credential to your LinkedIn profile, resume, or CV. Share it on social media and in your performance review

Training details

This is a live course that has a scheduled start date.

Live session

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

EveryEng is an amazing platform for engineers looking to upgrade their skills. The detailed lessons, practical approach, and expert guidance make learning enjoyable and effective. I highly recommend it!

EveryEng offers a fantastic learning experience with a great selection of courses and expert mentors. The platform is user-friendly, and the knowledge gained is highly practical. It's been a great journey so far!

I was skeptical at first, but EveryEng's training programs really delivered. I gained the skills and confidence to take on challenging projects and advance my career. Highly recommended!

EveryEng is a game-changer in engineering education. The platform provides high-quality courses, interactive learning experiences, and excellent mentor support. It has significantly helped me grow in my engineering career.

I was searching for a reliable platform to expand my engineering knowledge, and EveryEng exceeded my expectations. The content and courses are well-structured, informative, and taught by experienced professionals. A great platform for Engineers!