Comprehensive Static and Dynamic Slug Flow Analysis Using CAESAR II

Anup Kumar Dey

Owner of https://whatispiping.com/

$ 35

2 already enrolled!

Beginner course for learners

Comprehensive Static and Dynamic Slug Flow Analysis Using CAESAR II

Trainers feedback

4

(19 reviews)

Anup Kumar Dey

Owner of https://whatispiping.com/

Course type

Watch to learn anytime

Course duration

204 Min

Course start date & time

Access anytime

Language

English

This course format through pre-recorded video. You can buy and watch it to learn at any time.

Why enroll

Mastering "Slug Flow Analysis in Caesar II (Both Static and Dynamic)" elevates career growth for pipe stress engineers, designers, and analysts in the oil and gas, chemical, and process industries. Professionals can transition into senior roles like Lead Pipe Stress Engineer, Slug Flow Specialist, or Dynamic Analysis Expert, or specialize in slug flow analysis, piping system optimization, and multiphase flow simulation. Expertise in static and dynamic slug flow analysis in Caesar II enhances job prospects, earning potential, and leadership opportunities, ensuring accurate and reliable piping system design and operation in complex multiphase flow scenarios.

Opportunities that awaits you!

Earn a course completion certificate

Add this credential to your LinkedIn profile, resume, or CV. Share it on social media and in your performance review

Course details

Piping systems play a crucial role in various industries, facilitating the transport of fluids from one point to another. However, the dynamic nature of fluid flow can lead to complex phenomena such as slug flow, which presents challenges for design and analysis. Caesar II, a widely used software for pipe stress analysis, offers powerful tools for both static and dynamic analysis of slug flow.

Understanding Slug Flow:

Slug flow is a multiphase flow pattern characterized by alternating slugs of gas and liquid phases in a pipeline. This phenomenon can induce significant forces and stresses on the piping system, posing risks to its integrity. Key factors influencing slug flow include fluid properties, flow rates, pipe geometry, and system operating conditions.

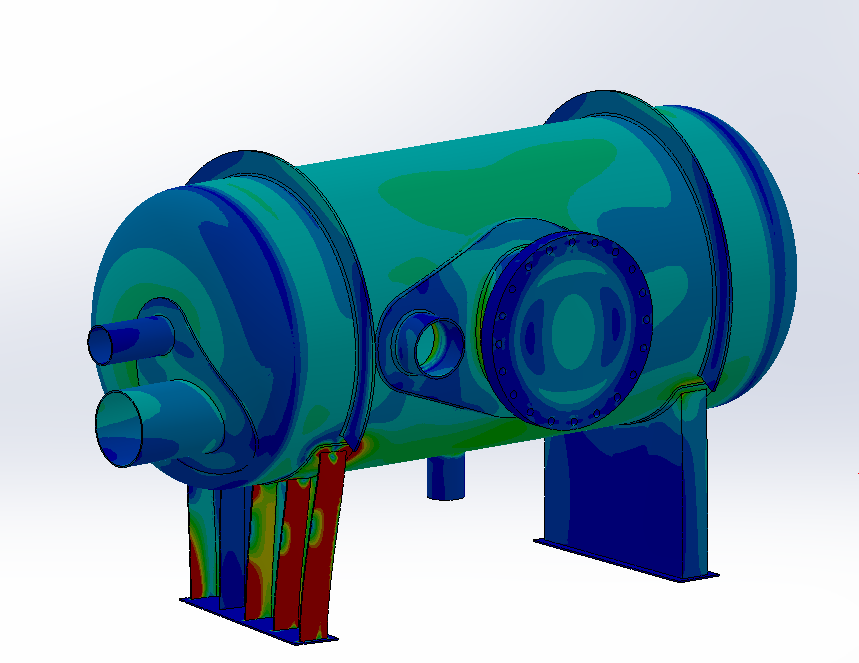

Static Analysis in Caesar II:

Static analysis in Caesar II involves the assessment of stresses and displacements in a piping system under static conditions, disregarding the time-dependent aspects of the fluid flow. This analysis is crucial for determining the system's response to steady-state loads and providing insights into potential failure points.

Geometry and Boundary Conditions:

Define the geometry of the piping system, including components, supports, and restraints. Establish boundary conditions to simulate the physical constraints of the system.

Material Properties:

Input material properties to account for the behavior of piping materials under static loads. Caesar II considers factors such as Young's modulus, Poisson's ratio, and thermal expansion coefficients.

Load Cases:

Define load cases corresponding to different operating scenarios and potential transient events. For slug flow analysis, load cases must capture the effects of slugs on the system.

Analysis Results:

Caesar II provides comprehensive output reports, detailing stress distribution, displacement, and support loads under static conditions. Engineers can use these results to identify critical areas and optimize the piping design.

Dynamic Analysis in Caesar II:

Dynamic analysis extends the assessment to include time-dependent factors, making it suitable for evaluating the effects of transient events such as slug flow. Caesar II's dynamic analysis capabilities enable engineers to study the system's behavior under changing conditions, providing a more realistic representation of its response.

Dynamic Loadings:

Specify dynamic loadings associated with slug flow, considering factors such as slug frequency, amplitude, and interaction with the piping system. Dynamic analysis helps identify resonance conditions and potential issues.

The static and dynamic analysis capabilities of Caesar II empower engineers to comprehensively evaluate the impact of slug flow on piping systems. By combining robust static analysis for steady-state conditions with dynamic analysis for transient events, designers can ensure the integrity and reliability of piping systems in the face of complex fluid flow phenomena. As industries continue to evolve, the importance of advanced analysis tools like Caesar II becomes increasingly evident in safeguarding the efficiency and safety of critical infrastructure.

Course suitable for

Oil & Gas Energy & Utilities Rail & Transport Mechanical Onshore Pipeline Piping & Layout

Key topics covered

Course content

The course is readily available, allowing learners to start and complete it at their own pace.

Online Course on Slug Flow Analysis in Caesar II (Both Static and Dynamic)

9 Lectures

204 min

Introduction

12 min

What is Slug Flow?

23 min

Static Analysis of Slug Flow

18 min

Dynamic Analysis of Slug Flow

36 min

Bonus 1: Slug Flow. Dynamical approach

5 min

Bonus 2: Gas Slug Flow Stress Analysis in Pipeline Systems: Dynamic Loads and Supporting

5 min

Bonus 3: Dynamic Stress Analysis of Slug Loads in Piping Systems | Modal & Time History Analysis in Caesar II

9 min

Bonus 4: Tackling Slug Flow Vibrations in Pipeline Design and Operations: Engineering Approaches

14 min

Detailed Bonus-Solving vibration problems in a two-phase flowline

82 min

Why people choose EveryEng

Industry-aligned courses, expert training, hands-on learning, recognized certifications, and job opportunities—all in a flexible and supportive environment.

- Industry Veteran

- Trainer Review

Anup Kumar Dey

Owner of https://whatispiping.com/

Questions and Answers

A: Slug flow refers to a two-phase flow pattern commonly encountered in pipelines, especially in oil and gas production. It is characterized by the intermittent and irregular flow of liquid slugs separated by gas pockets. This non-uniform flow leads to significant fluctuations in pressure and forces on the pipeline, which must be considered during design and analysis to ensure structural integrity. For more detailed information, you can refer to the API TR 24.2 or academic literature on multiphase flow dynamics.

A: Performing both static and dynamic analyses of slug flow is essential because static analysis provides the baseline stress levels under steady-state conditions, while dynamic analysis captures the transient loading and response due to slug impacts. Slug flow generates large, rapid pressure surges and forces that can cause vibrations and fatigue failures if not properly accounted for. CAESAR II's dynamic analysis capabilities allow engineers to simulate these conditions, ensuring the pipeline's design can withstand real operating scenarios. References to CAESAR II's dynamic analysis features can be found in their official documentation by Hexagon PPM.

A: CAESAR II models slug flow forces using transient force inputs based on user-defined slug characteristics such as slug frequency, length, density, velocity, and impact pressures. The software applies these forces as time-dependent loads on the piping system, allowing dynamic response simulations. These transient forces simulate the real-life effects of slugs traveling through pipelines, including hydrodynamic forces and sudden pressure changes. The detailed methodology is documented in CAESAR II's user manuals and case studies related to multiphase flow analysis.

A: Several challenges include accurately predicting slug characteristics (size, frequency, velocity), modeling the complex hydrodynamic forces involved, and capturing the dynamic response of the pipeline structure under transient loading. Additionally, slug flow can cause fatigue damage due to cyclic loading, making it necessary to perform fatigue analysis alongside dynamic simulation. Variability in operational conditions and multiphase flow regimes add complexity to the analysis. Engineers often rely on field data, empirical correlations, and advanced simulation tools like CAESAR II to address these challenges.

A: Setting up a dynamic slug flow analysis in CAESAR II involves several key steps: first, define the piping geometry and material properties; second, perform a static stress analysis to establish baseline conditions; third, input slug flow parameters such as slug length, velocity, density, frequency, and impact pressure; fourth, configure transient load cases representing slug flow forces; and finally, run the dynamic analysis to evaluate the pipeline's response to these loads. Post-processing includes examining displacement, stress time histories, and checking against allowable limits. CAESAR II’s documentation provides tutorials and examples that guide users through this process.

A: For in-depth understanding, I recommend the following resources: the 'API Recommended Practice 24.2' series for guidelines on multiphase flow and slug analysis; 'Pipeline Rules of Thumb Handbook' by E.W. McAllister for practical insights; academic papers on multiphase flow dynamics available through journals like the Journal of Energy Resources Technology; and Hexagon PPM's official CAESAR II user manuals and training materials for software-specific guidance. Online courses and webinars from industry experts can also provide valuable hands-on experience.

More from Same Author

- Technical Courses

- Articles

4 (19)

Watch to learn anytime

28

E-Learning

Unlimited access

Instructor led live training

118

Online

Live courses

October 13

15 Hrs

5

Instructor led live training

893

195

Online

Live courses

September 15

1 Hrs

Earning and Growth option in same Industry Domain

- Pre-recorded

- Online live session

- Offline

- Articles

4 (19)

Watch to learn anytime

3675

2

E-Learning

Unlimited access

5

Watch to learn anytime

3758

2

E-Learning

Unlimited access

5

Watch to learn anytime

246

1

E-Learning

Unlimited access

More Training & Development option to expand your reach

- Technical courses

- Soft-skill courses

- Seminars & Conferences

- Articles & Blogs

5

Instructor led live training

459

1

Online

Live courses

September 22

9 Hrs

Beginner

4 (23)

Instructor led live training

335

1

Online

Live courses

October 11

14 Hrs

Advanced

4 (23)

Instructor led live training

541

Online

Live courses

October 11

4 Hrs

Intermediate